In modern drilling, staying in the reservoir is everything. Every extra meter drilled inside the productive zone means more hydrocarbons recovered and higher project profitability. Yet operators often face blind spots in real-time formation evaluation, particularly when relying on a single data source.

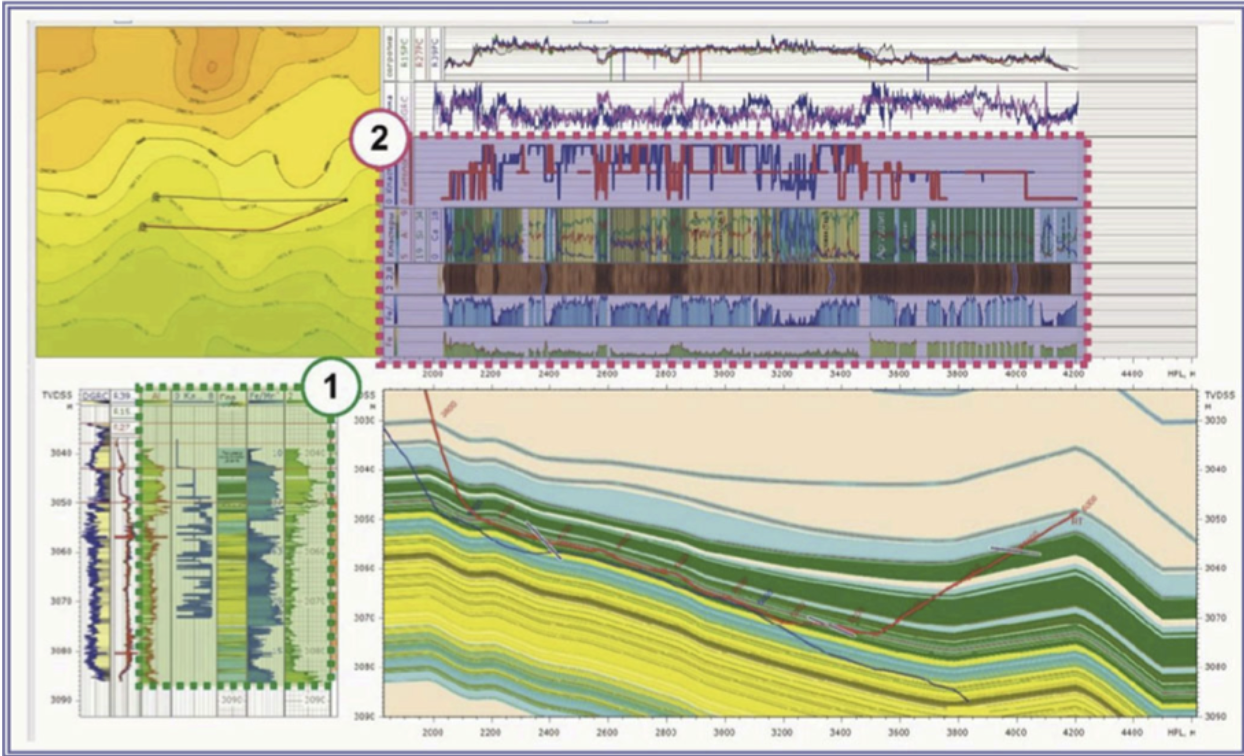

This case study highlights how integrating cuttings analysis with logging-while-drilling (LWD) data provides sharper, faster geosteering decisions.

Traditional geosteering workflows depend heavily on LWD data. While invaluable, LWD readings are not always enough to capture subtle lithological variations or identify formation boundaries in real time. Meanwhile, drill cuttings (samples already available on every rig) often go underutilized, treated as a byproduct instead of a decision-making tool.

The result?

Operators may react late to geological changes, slipping into non-productive zones or drilling extra footage that adds cost without delivering value.

By combining cuttings analysis with LWD density and gamma-ray logs, operators gain a multi-dimensional view of the formation while drilling. Cuttings provide direct lithological evidence, while LWD delivers continuous real-time measurements.

Together, these datasets complement each other:

In the Abu Dhabi field trial, engineers implemented this integrated workflow while drilling a complex carbonate well. The results were clear:

For drilling teams and asset managers, this approach translates directly into business value:

It’s a practical innovation: no new downhole tools are required. Instead, it makes smarter use of the data already available on every rig.

The Abu Dhabi case study shows that integrating cuttings and LWD data is a pathway to smarter, more profitable drilling. By combining direct geological samples with real-time logging, operators can eliminate blind spots, react faster, and maximize the value of every well drilled.

Adaga Solutions is helping operators put this integrated workflow into practice today. Want to see how it could work on your next project? Contact us to learn more.