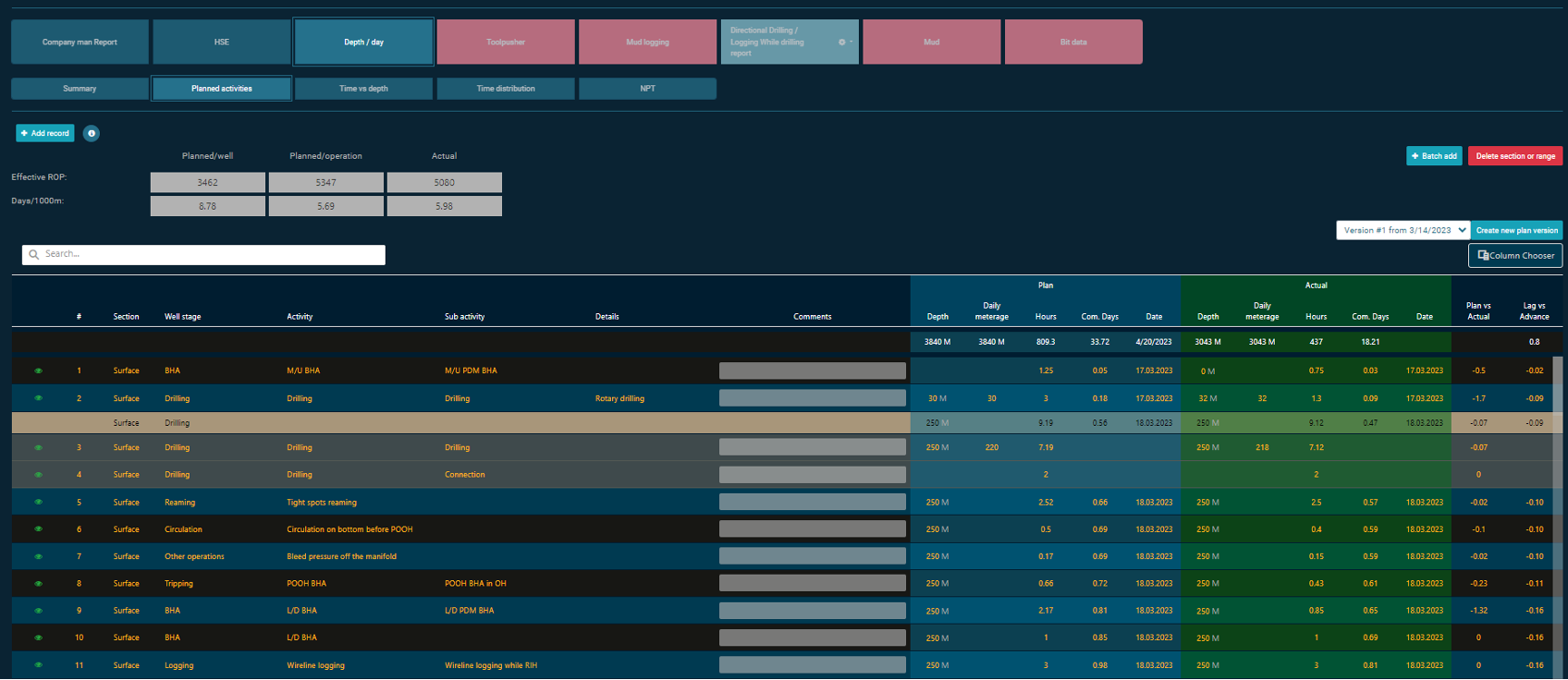

Time Vs Depth

The application allows you to create a work program with selected time and depth intervals

Automatic time-to-depth graph generation

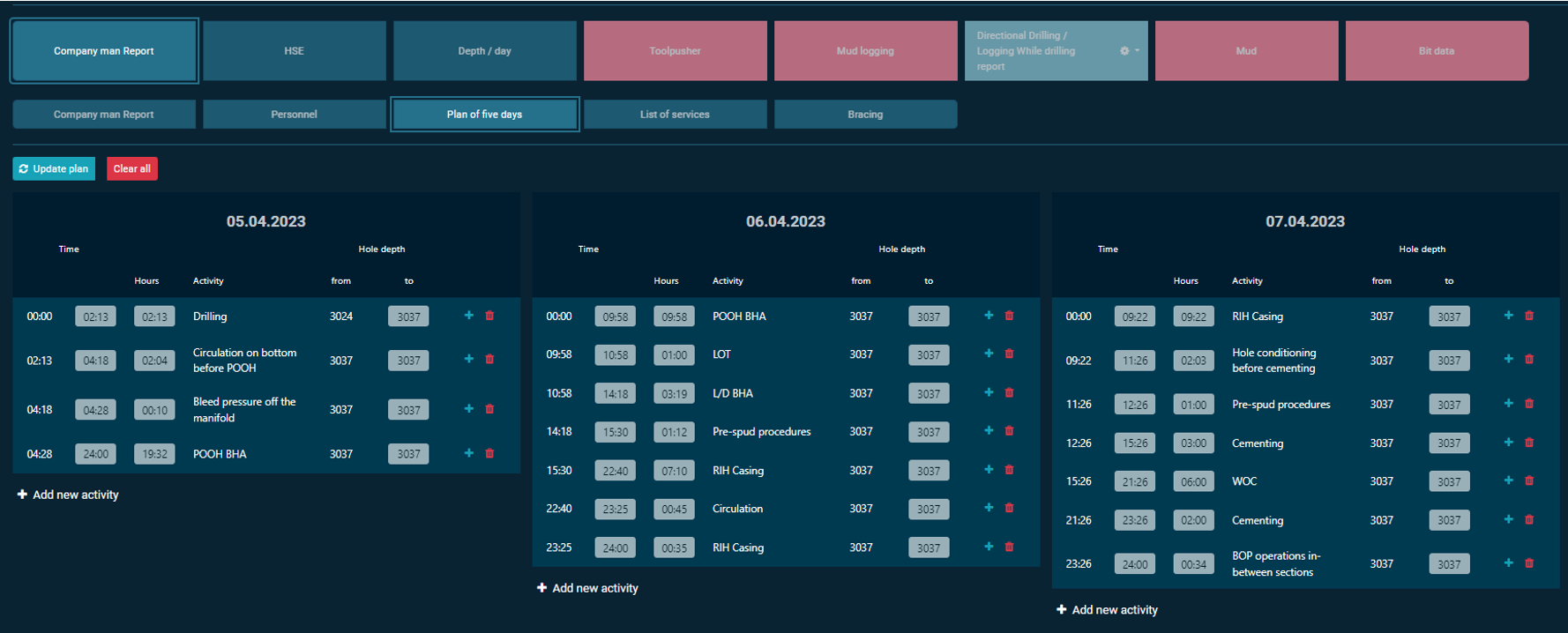

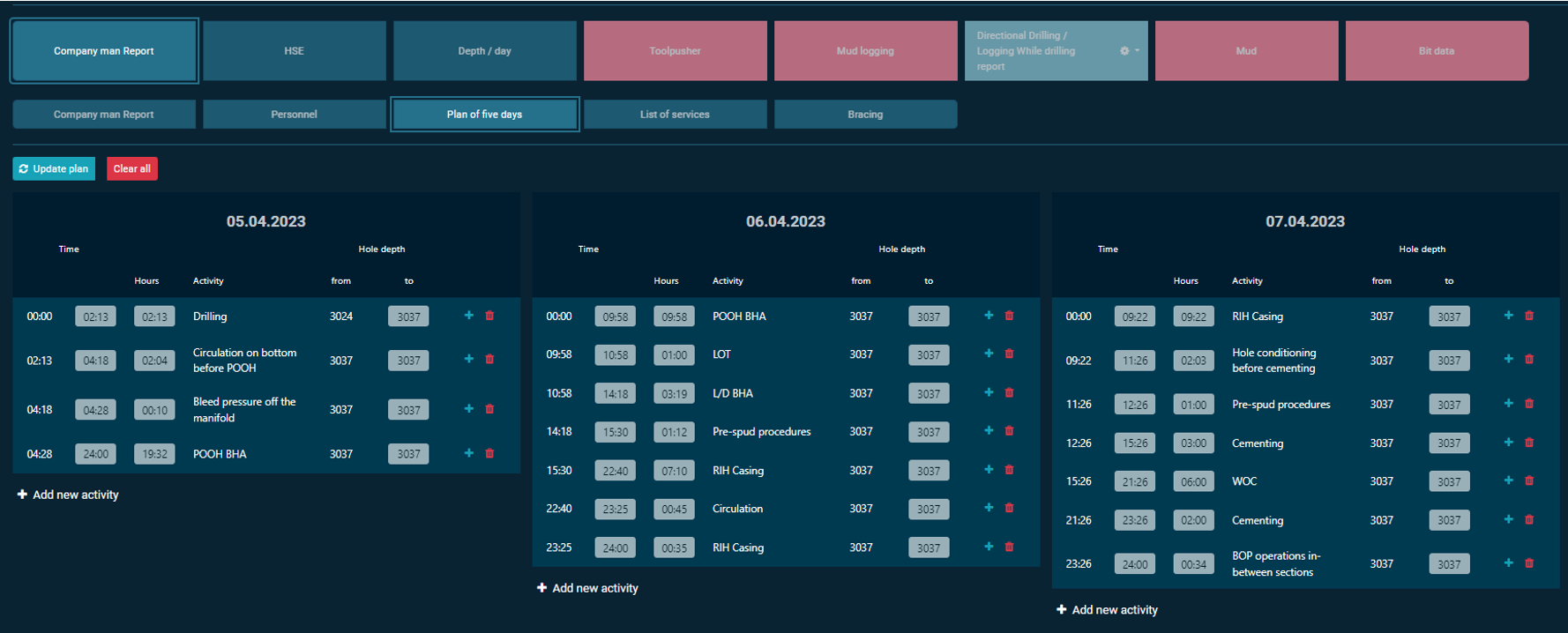

5 days detailed plan based on the actual activities

Activities, operations, and NPTs can be created with the link to the responsible party and detailed root causes

Available libraries while creating work program time balance and NPT categories

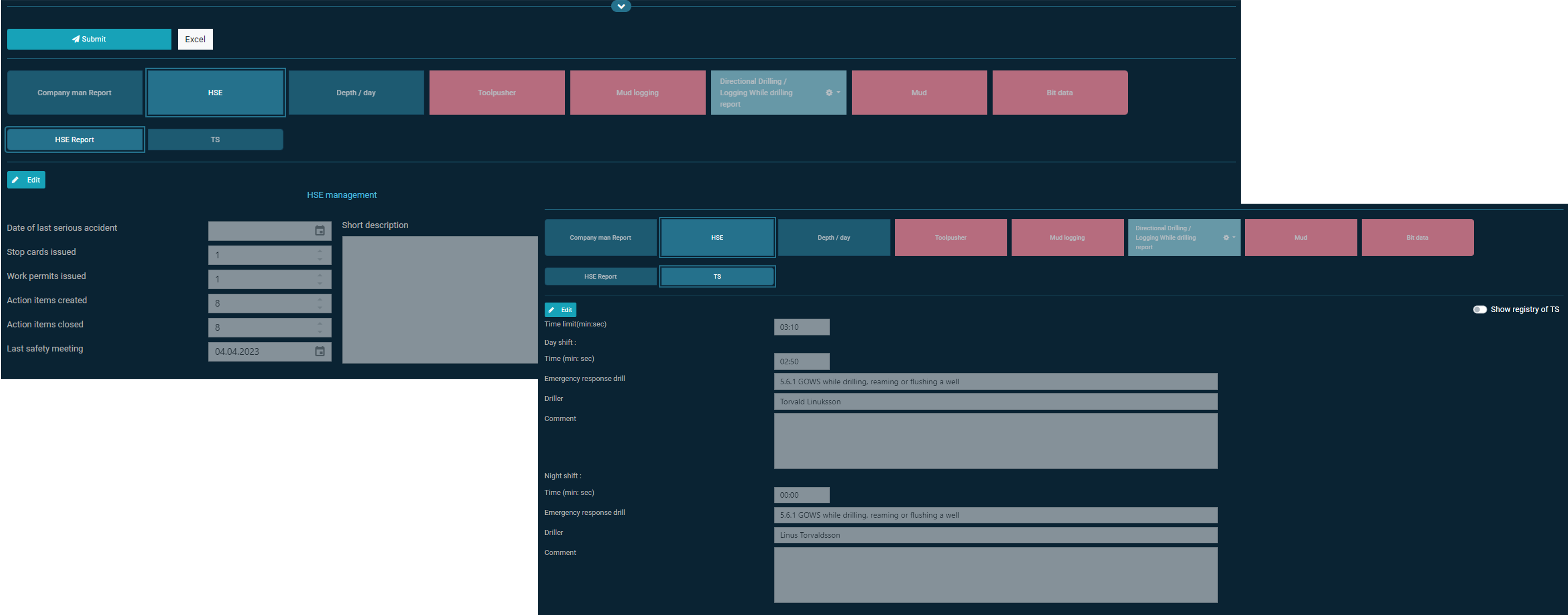

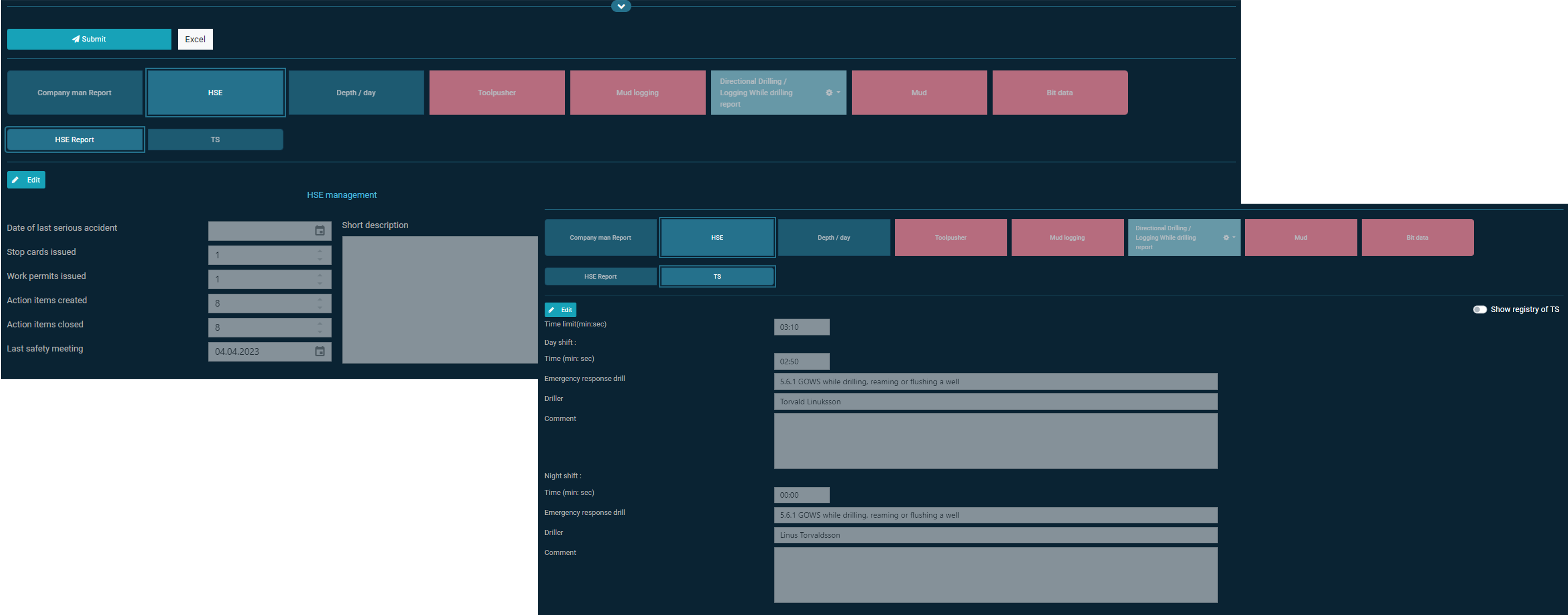

The Company Man Section

The company man section is equipped with the well information, personnel, and service companies

Meeting tracking

Casing data and cementing operations

The chronology of all well operations with filtering tools

Implement advanced scheduling techniques to plan daily operations meticulously, ensuring optimal utilization of resources.

Employ automated processes to bypass tedious and repetitive tasks, such as report reading and summarization, redirecting focus towards high-impact activities that yield significant returns.

Rigsite Service Companies Sections

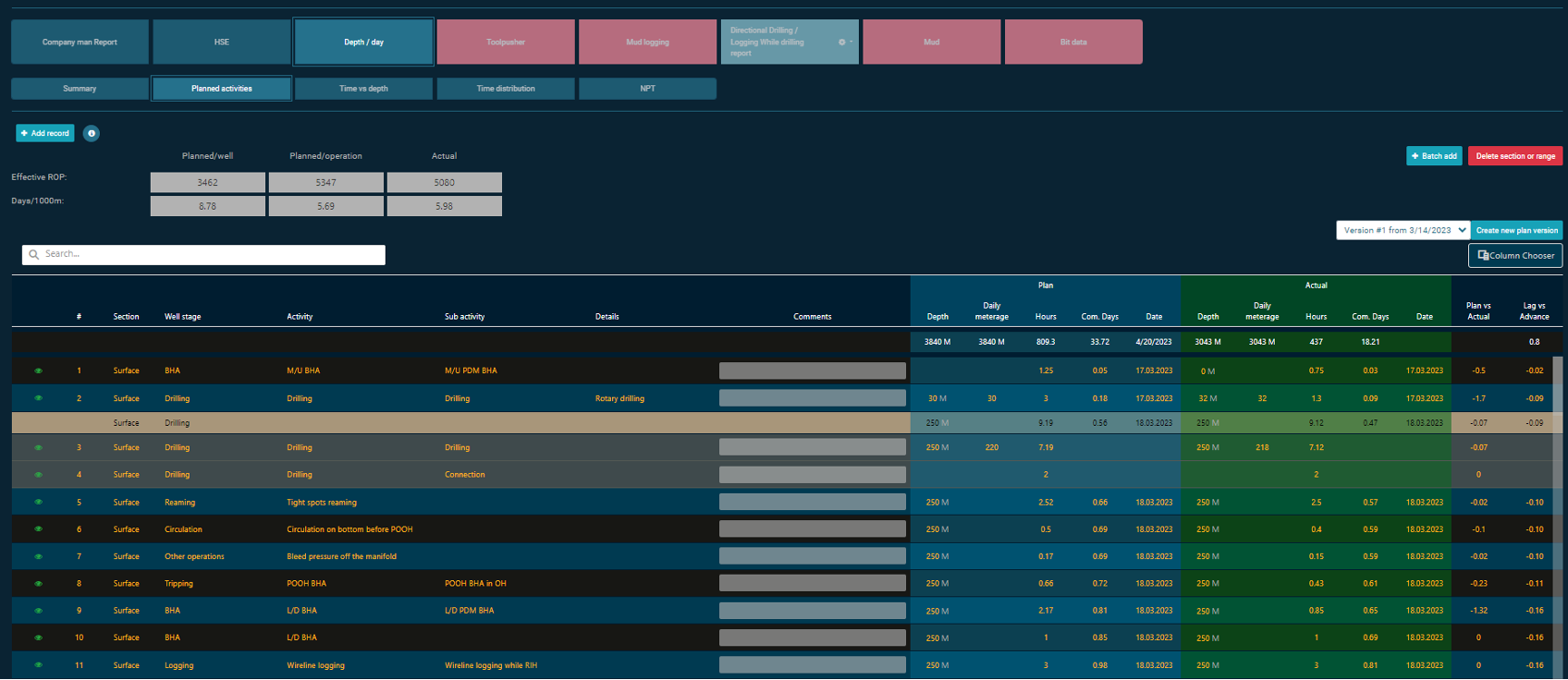

Compare and analyze the variance between planned and actual progress using comprehensive rig reports.

Streamline reporting and data handling processes to maximize efficiency and effectiveness.

Integrate the platform with ePlan to gain insights into how daily operations impact the broader perspective of planned well activities.

Mudlogging – time balance

DD – trajectories, runs, BHAs

Toolpoosher – equipment working hours

Mud services – chemicals calculation, mud parameters, volumes

Bit services – bit wearing tracking

Lesson Learned Database

Inside the eReport we have a lessons learned database “Events”. This database saved best practices for efficient operations as well as lessons learned and root causes from incidents and NPTs. This tool helps to propagate gained experience for the upcoming wells. Different objects can be attached to the case with the approval stages and mailing distribution list.

Identify the root causes of Non-Productive Time (NPT) through thorough analysis.

Categorize NPT incidents by company, well stage, underlying causes, and other relevant factors.

Establish a lessons learned system tailored to facilitate the dissemination of best practices among different rigs.