When it comes to horizontal drilling, every foot counts. The closer you keep the wellbore inside the productive reservoir, the more profitable the project becomes. But making those decisions in real time isn’t easy—especially when your sensors are sitting a few meters behind the drill bit. That delay often causes costly detours into non-productive rock.

For operators under pressure to improve drilling efficiency, avoid wasted footage, and maximize reservoir contact, the difference between success and setback often comes down to how quickly lithology changes can be detected.

In carbonate reservoirs and other complex formations, density logging plays a critical role in identifying rock properties and boundaries. But there’s a catch. Conventional logging-while-drilling (LWD) density tools sit well above the drill bit. This creates a “blind spot” between where the bit is cutting and where the sensor is measuring.

By the time the tool registers a density change, the drill may already have passed through valuable sections—or wasted hours cutting into non-productive layers. The result? More non-productive time, increased costs, and less hydrocarbon recovery.

Adaga Solutions has developed a smarter way to bridge this gap. By combining standard engineering drilling parameters—such as weight on bit, hook load, rotation speed, and rate of penetration—with LWD density information, operators can calculate rock density directly at the bit.

Think of it as swapping a rear-view mirror for a set of headlights. Instead of waiting for delayed measurements from behind the drill, the software delivers predictive, real-time insights right where decisions are made. This makes it possible to anticipate lithology shifts, adjust trajectories faster, and steer the wellbore with precision.

This approach doesn’t require additional tools downhole. Instead, it unlocks new value from the drilling data operators are already collecting.

Real-time density at the bit isn’t just an academic breakthrough—it delivers tangible results for drilling teams and project economics.

For operators navigating thin or variable pay zones, these benefits directly translate into better performance and improved project profitability.

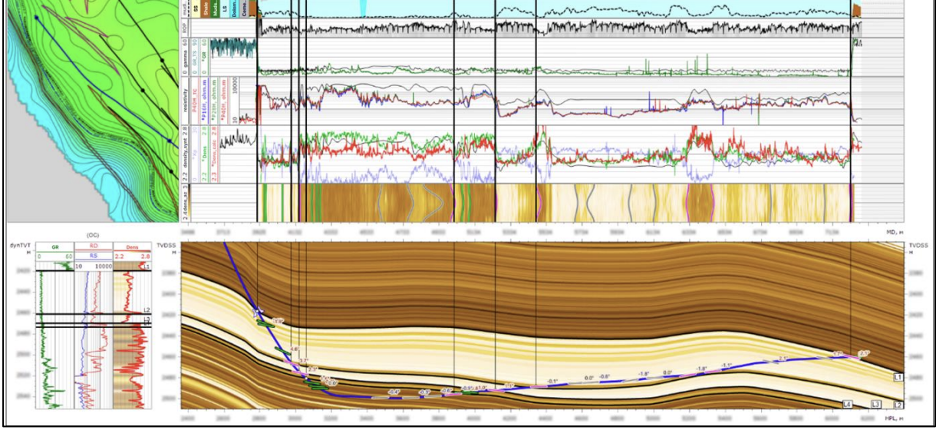

The approach isn’t just theory—it’s already delivering results in the field. In one carbonate reservoir project, engineers applied Adaga’s calculated density at the bit workflow while drilling Well #8.

With the ability to “see” rock density in real time, the team avoided unnecessary footage through non-productive rock, made faster steering decisions, and kept the drill in the reservoir’s most productive interval for longer.

The case validated what engineers suspected: density prediction at the bit provides a strong correlation with LWD logs, while reducing reliance on delayed sensor data.

The future of geosteering isn’t about adding complexity—it’s about making the most of the drilling data already at your fingertips. Calculating density at the bit closes the gap between action and insight, enabling operators to:

At Adaga Solutions, we’re proving that smarter geosteering software doesn’t just improve well placement—it improves bottom-line results.